Profile

PMPO is specialized in the manufacture of two types of products: “lobe-type pumps” and “filtration systems”. Various applications are possible, also thanks to the creation of customized solutions: PMPO can count on qualified staff, equipment, test benches and analytical laboratories, carryingout research and development activities.

PMPO is specialized in the manufacture of two types of products: “lobe-type pumps” and “filtration systems”. Various applications are possible, also thanks to the creation of customized solutions: PMPO can count on qualified staff, equipment, test benches and analytical laboratories, carryingout research and development activities.

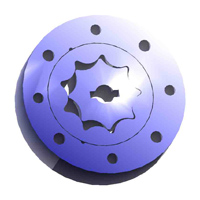

The main applications for pumps is in the oil–pressure field. However applications with fluids that are different from oil are also possible, like for instance with isocynate or polyol for the formation of polyurethane. The introduction of new technologies allowed reaching high performances in terms of flow-rate and pressure, giving priority to their long-life and quietness. The pumps are miniaturized (external diameter 6 cm), they are made with anti-binding material; they very reliable (the warranty can be extended up to 3 years). TLobe-type pumps are used for lubrication or, in general, for oil transport; besides supplying pumps with this function, PMPO has also created models that can reach the pressure of 120 bars and a rotation speed of 7000 rpm. Finally, these pumps offer a strong economical advantage.

The main characteristic of the filtration systems is that they are completely automatic and do not use additives to obtain the filtration. The filtration level is one of the highest, compared to international standards. The filter separates the solid particles inside the dirty fluid: applications are many, but PMPO is specialized in lubricant/coolant fluids of machine tools. The machine has tanks to contain the dirty and clean fluids, feeding pumps for the filtering parts, boost pumps for the filtered fluid, a device for the automatic regeneration of filtering parts, a device for automatic sludge extraction, a device for sludge drying process. PMPO has been working in this field for years; the company is currently creating innovative systems, thanks to the remarkable experience in solving different problems concerning lubricant/coolant fluid filtration. The use of this system provides microfiltration, allowing high-quality performances and long life to the tools and the fluids. All this is done protecting the environment and working conditions as well. The filtering system can be customized; therefore, it can meet every necessity.

The main characteristic of the filtration systems is that they are completely automatic and do not use additives to obtain the filtration. The filtration level is one of the highest, compared to international standards. The filter separates the solid particles inside the dirty fluid: applications are many, but PMPO is specialized in lubricant/coolant fluids of machine tools. The machine has tanks to contain the dirty and clean fluids, feeding pumps for the filtering parts, boost pumps for the filtered fluid, a device for the automatic regeneration of filtering parts, a device for automatic sludge extraction, a device for sludge drying process. PMPO has been working in this field for years; the company is currently creating innovative systems, thanks to the remarkable experience in solving different problems concerning lubricant/coolant fluid filtration. The use of this system provides microfiltration, allowing high-quality performances and long life to the tools and the fluids. All this is done protecting the environment and working conditions as well. The filtering system can be customized; therefore, it can meet every necessity.